Experience is our advantage.

Encore is the most qualified assemblage of scheduling and delay analysis professionals. Our clients realize the benefits of quality scheduling programs, well-documented projects, early resolution of disputes, and practical application of technology.

Project Services

Encore provides complete delay analysis and scheduling solutions for your construction organization. We provide full, end-to-end professional services on an ongoing basis, from project start-up to successful closeout.

Software

Encore Group offers a complete line of construction scheduling software for your project management and scheduling solution needs. We support every facet of your construction scheduling software needs.

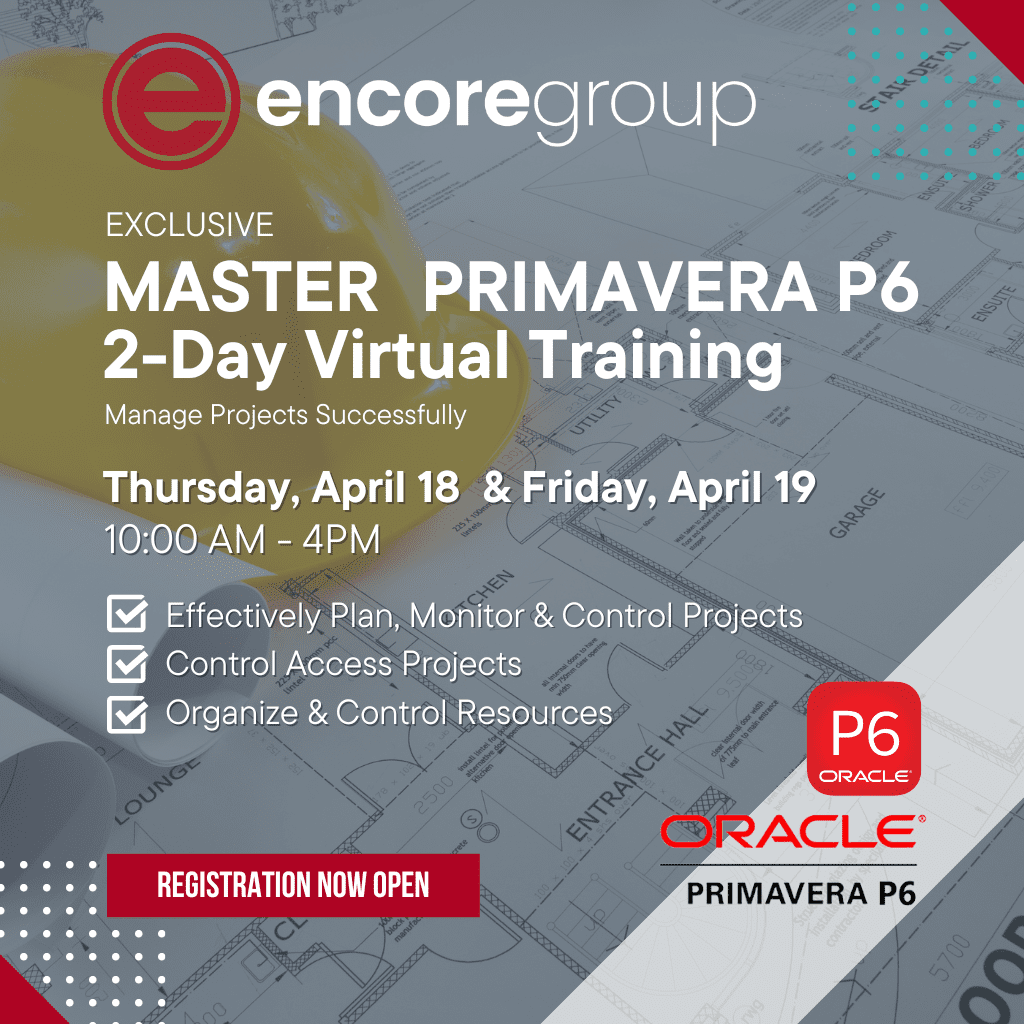

Training

Scheduling Services

Scheduling

Claims/Litigation

Scheduling Software

Resources for Construction Scheduling

Encore Group offers complementary resources for schedulers, including, templates and layouts for Primavera P6, Schedule Validator and Powerproject.

Powerproject

Asta Powerproject Training Resources

Primavera P6

Primavera P6 Training Resources

Schedule Validator

Schedule Validator Training Resources

Upcoming Events

Schedule Validator's 2024 User Conference

Setting Goals for Your Scheduling Department

Primavera P6 Live Virtual Training